A company’s experience alone is no guarantee of good products, since aspects such as speed and excellence in the service and customer care are key factors too. These are the principles that govern the joint operations of AVINENT and the international group Core3dcentres, which has an extensive track record of providing a milling service for prosthetic structures on implants from a wide range of materials that are suitable for use with most connections on the market. And all of this can be done in record time, just 48 hours!

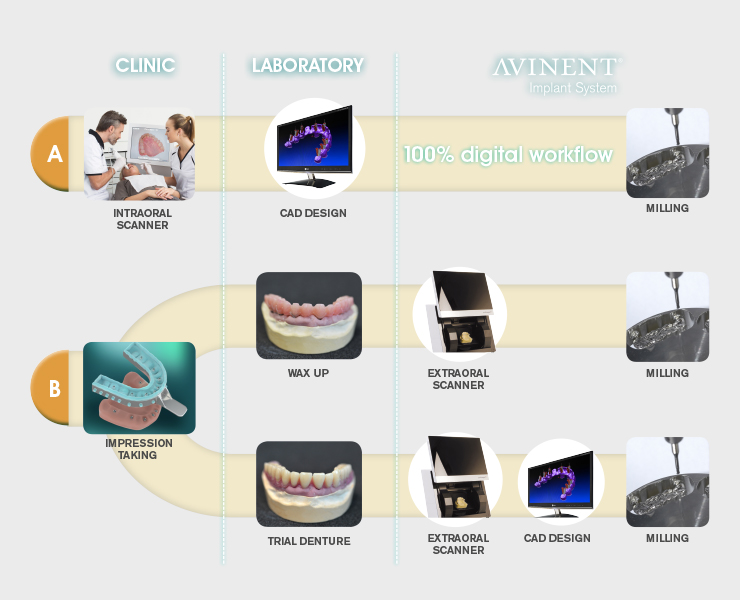

AVINENT is more than a milling center because it covers every stage of the computer-aided design and manufacturing (CAD-CAM) of customized prostheses in the digital era: digital scanning, CAD and high-speed machining (HSM) using new technologies and new materials, with the possibility of interpreting 3D files, models and scans (.stl) for the subsequent machining of structures. It is an immense platform capable of offering solutions that are open to all kinds of digital technology for creating customized structures for every need.

AVINENT offers a variety of ways to receive orders

According to Mr. David García, the director of the Laboratorio Garbident in Vitoria, Spain, there are three basic things that describe AVINENT’s service: “a very fast and reliable delivery service, a very good standard of quality and competitive prices”. Mr. Amador Ratero, the manager of Laboratorio Dental Codenta in Madrid, Spain, adds that “centers like ours are especially appreciative of the speed and reliability because we are working to very short turnaround times. They offer us delivery options that are one or two days shorter than other milling centers”. AVINENT’s milling center is unique because of its speed – it can deliver customized milled bars in a record time of 48 hours from the moment they are ordered.

A world of materials and design possibilities

From the various materials that AVINENT uses in its structures, cobalt-chrome (CoCr) and titanium (Ti) stand out in particular. The characteristics of these components ensure better resistance to corrosion and, therefore, fewer possibilities of defects appearing on the surface, such as cracks in ceramic finishes. In addition, the fully machined process means that the structures have greater stability and benefit from millimetric precision, with minimal chances of error. Mr. Juan Golobart, the director of Laboratorio Odontecnic in Hospitalet de Llobregat, Spain, explains that “the key to successful treatment lies in the ability to decide beforehand what material will suit each patient best. In this respect, AVINENT offers peace of mind in knowing that it is constantly innovating with a wide range of quality materials”.

In addition, AVINENT has an extensive library of connections for most of the design software packages on the market. According to Mr. David García, AVINENT can manufacture nearly everything that anyone wants to do in digital dentistry today.

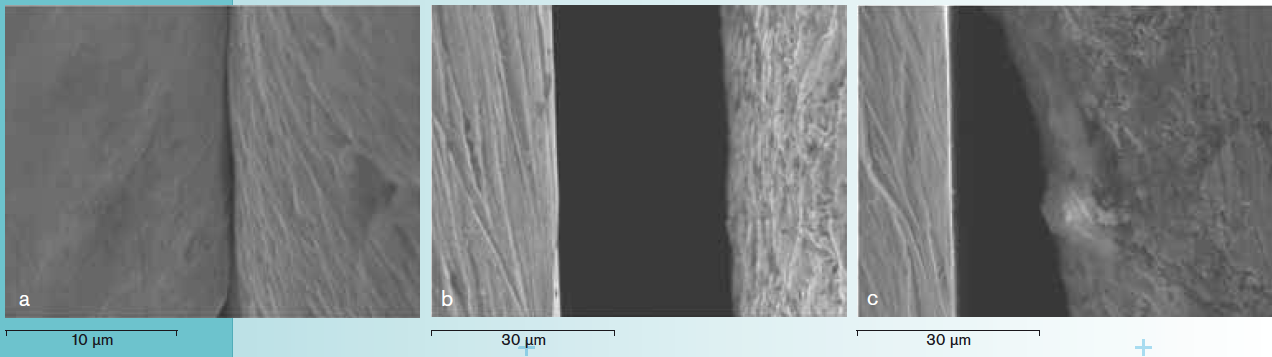

Quality, precision and reliability in creating metal structures

AVINENT’s complex-prosthesis manufacturing processes are, unlike others, subtractive. In other words, the prosthetic structure is obtained from high-quality blocks of material. The firm’s digital technology and equipment mean that these CAD-CAM processes are very precise, which in turn means that the passive prosthesis-implant fit is perfect. See the article “Analysis of the misfit of dental implant-supported prostheses made with three manufacturing processes” (J Prosthet Dent 2014, 111:116-123).

Mr. Emilio Cuadrón, the manager of Laboratorio Cuadrón Álvaro in Madrid, Spain, says “I value the passivity of fit of these structures and, therefore, their precision. As far as our center is concerned, I’d also point out the convenience of not having to take on the production of metal structures”. Mr. Amador Ratero highlights “the angulation correction possibilities that AVINENT’s milled bars offer in comparison to those from other centers”.

In turn, the centering devices and angulation correction are very important features and services that, besides facilitating work in the laboratory, customize the milling works and make the process of placing and removing the definitive prosthesis much more convenient and precise. So, when a professional performs maintenance and adaptation tasks, it is possible to eliminate any potential maneuverability complications that tight connections or implants placed with different angulations might cause. On the other hand, AVINENT’s milled bars allow screw housings to be placed on the occlusal sides of the prosthesis, which leads to a better appearance of the final tooth and to biomechanical improvement in the prosthesis.

AVINENT’s milled bars include the screws corresponding to the connection for their placement. The design and mechanical behavior of the existing connection is therefore respected, preventing mistakes and a bad fit.

Mr. Juan Golobart explains that “only firms with a significant business vocation like AVINENT are able to perfectly deliver what they promise”. He concludes by saying that “in a tough market like ours, trust in quality and service is essential”.