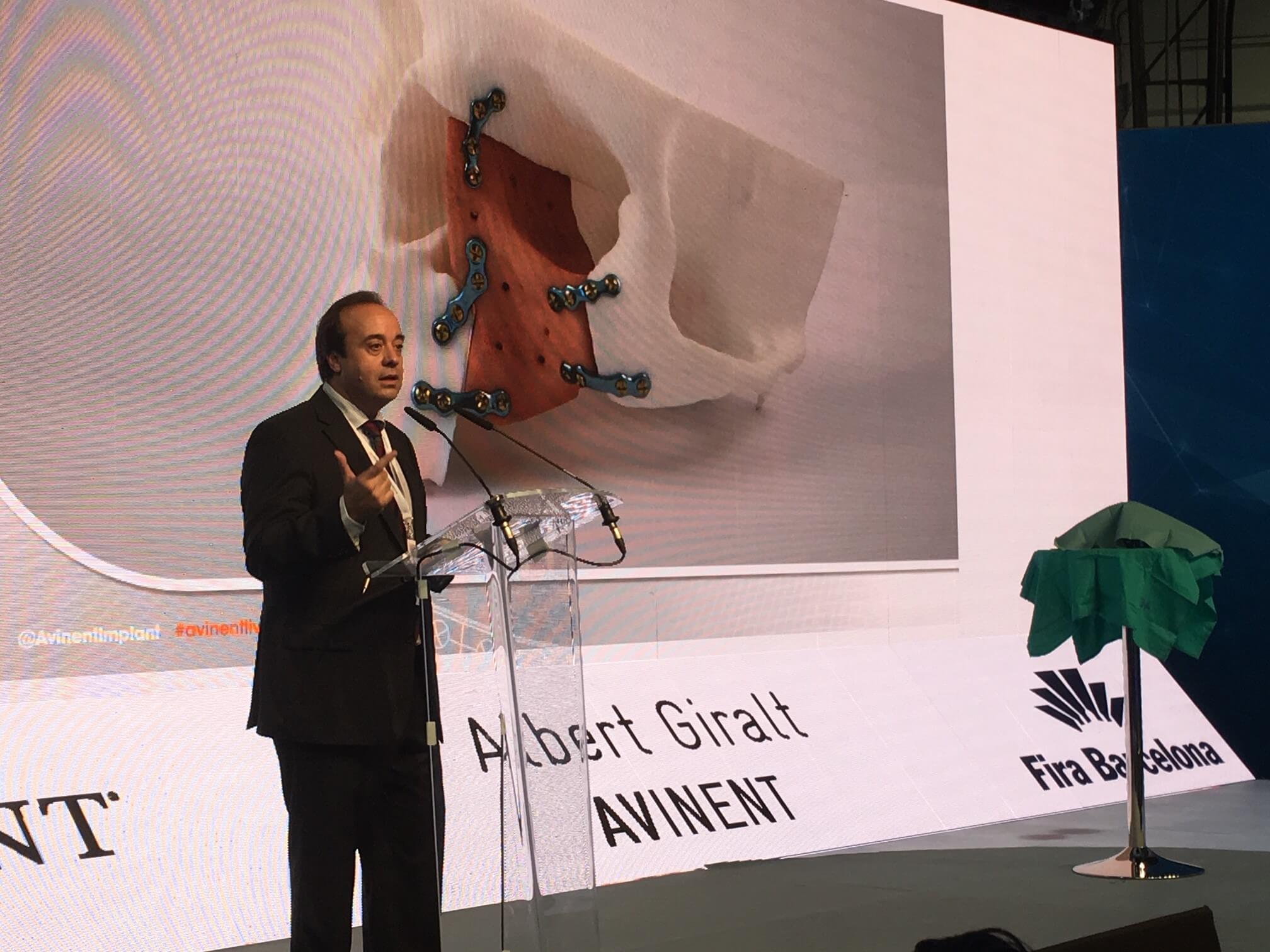

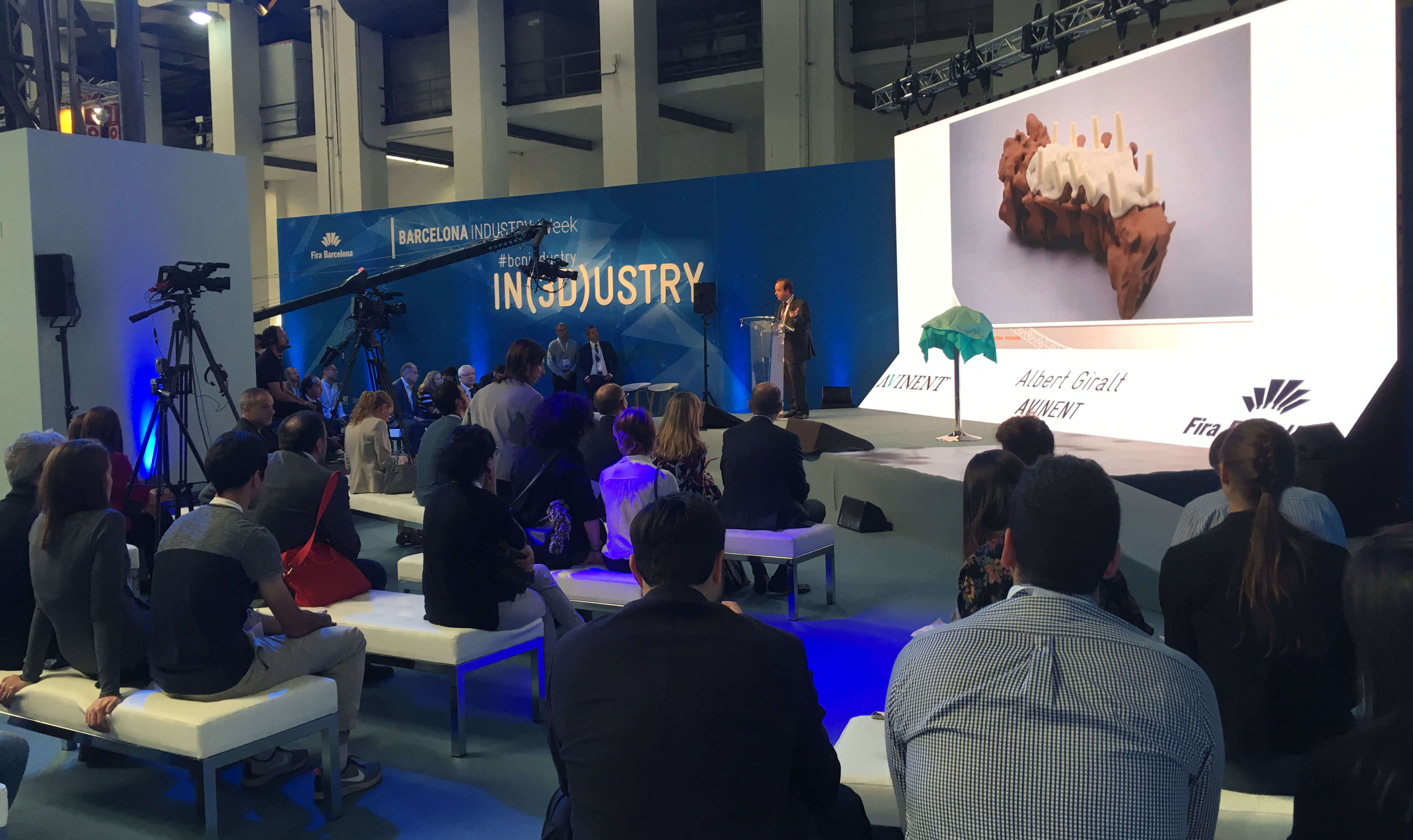

“It won’t be long until it will be impossible to think that diagnoses used to be made without the help of 3D printing”. With this prophetic phase, Albert Giralt, CEO of AVINENT, illustrated on Wednesday, within the framework of the In3dustry and Healthio congresses, held at the Fira de Barcelona, the enormous potential of 3D printing technologies in the medical sector. Giralt emphasised that “this is only the beginning of what will become a tool that will be used more and more frequently at hospitals and medical centres”, and he insisted that “nowadays, when we talk about 3D printing, we are no longer talking about the future, but the present”.

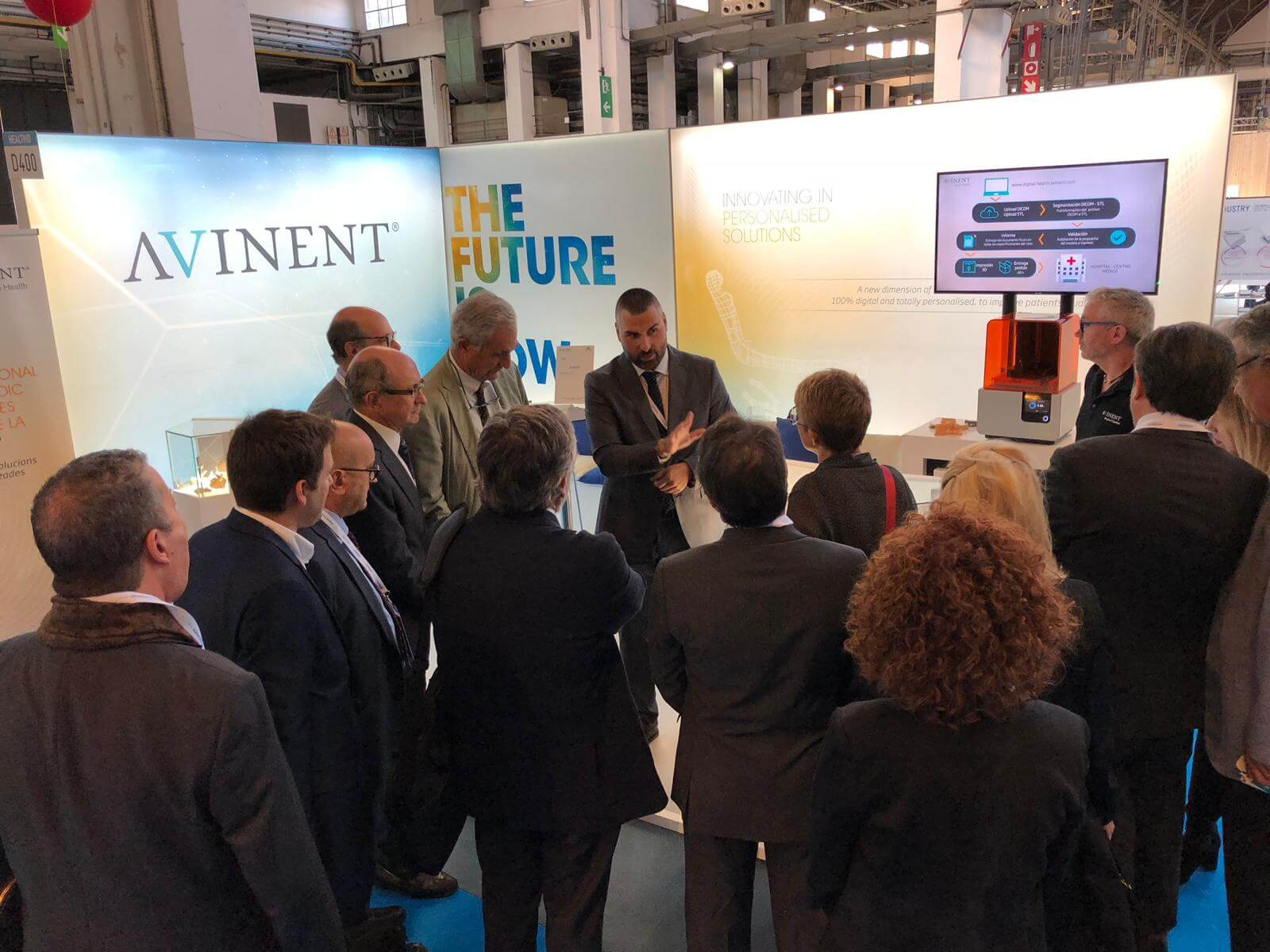

AVINENT, with a presence at both congresses held at Fira de Barcelona from Tuesday 16 to Thursday 18 October, has once again demonstrated through its stands and presentations why medical centres and hospitals should throw open their doors to 3D printing, the benefits of additive manufacturing technologies, and why it has become the ideal partner in which to entrust the whole service and support to initiate themselves in the new ways of working.

At In3dustry, dedicated to 3D printing technologies, AVINENT promoted, jointly with the Fundació Althaia and under the name “3D for Health. Success stories”, the presentation of twelve success stories in 3D printing applied to the healthcare field. On each of the three days, those attending heard the testimony of four doctors who told of real success stories where they have used the 3D printing technology provided by AVINENT. In total, twelve medical professionals from different centres of prestige, who have worked shoulder to shoulder with the company, described how personalised anatomical models, cutting guides, splints and implantable dentures, all thanks to 3-D printing, is revolutionising the sector, streamlining the work of medical professionals and considerably improving the results for the patient.

One of the doctors who, on 16 October gave a presentation of the success stories within the “3D for Health. Success Stories” cycle of seminars, is Javier Rodríguez, the Head of the Maxillofacial Surgery service at the Joan XXIII Hospital in Tarragona. Rodríguez, an expert in orbital surgery who regularly works with AVINENT, described the advantages of customised orbital surgery (achievable thanks to 3D printing technologies, compared to traditional orbitals. In Doctor Rodríguez’s opinion the leap is enormous: “The benefits of customised orbital surgery are many. It is easier to use, the approaches are fewer, therefore, the surgery is less invasive, and surgery time is reduced”. However, Javier Rodríguez is of the opinion that there is greater pre-op time, a higher economic cost and very quick delivery times are required”. It was here that Doctor Rodríguez points out that “this issue is resolved with AVINENT, it is a differentiating fact compared to other companies, as in just only a day and a half after placing the order we can already be operating. AVINENT is the only company that can guarantee these delivery times, a key aspect when talking about primary trauma”.

Doctor Carles Martí Pagès, the maxillofacial surgeon at Hospital Clínic in Barcelona, gave a short presentation this Thursday at the In3dustry Congress regarding the application of 3D printing for a temporomandibular joint (TMJ) prosthesis. Doctor Martí stated that “the 3-D printing techniques are absolutely essential to the success of the TMJ prostheses.” “The big difference” -he continued- “is that without personalised surgery, we would have to adapt the size and shape of the bone to the prosthesis. Today it’s just the opposite: it is the prosthesis which is adapted to the size and shape of the bone.”

3D printing, also a key role in training

The advantages don’t end there: the printing of 3-D models also represents a change of paradigm with regard to training. Doctor Pablo Collera, Director of the General Surgery and Digestive System Service for the Althaia Foundation in Manresa, and who on Wednesday gave one of the twelve conferences together with Doctor Bartomeu Ayala on a transanal/transabdominal rectal neoplasty practice using a model printed at AVINENT, highlighted just after started his speech that “we believe that one of the areas that is not developed and has a long way to go is that of attempting to experiment using models in order to be able to reproduce surgeries and to be able to teach surgical techniques.” According to Doctor Collera, one of the benefits in the use of models for training “is the price, given that access to animals or cadavers for practising is always difficult and expensive.” The Director of the General Surgery and Digestive System Service for the Althaia Foundation concluded that “if when we are teaching medicine we are showing virtual models, the logical step would be to use models printed in 3D.”

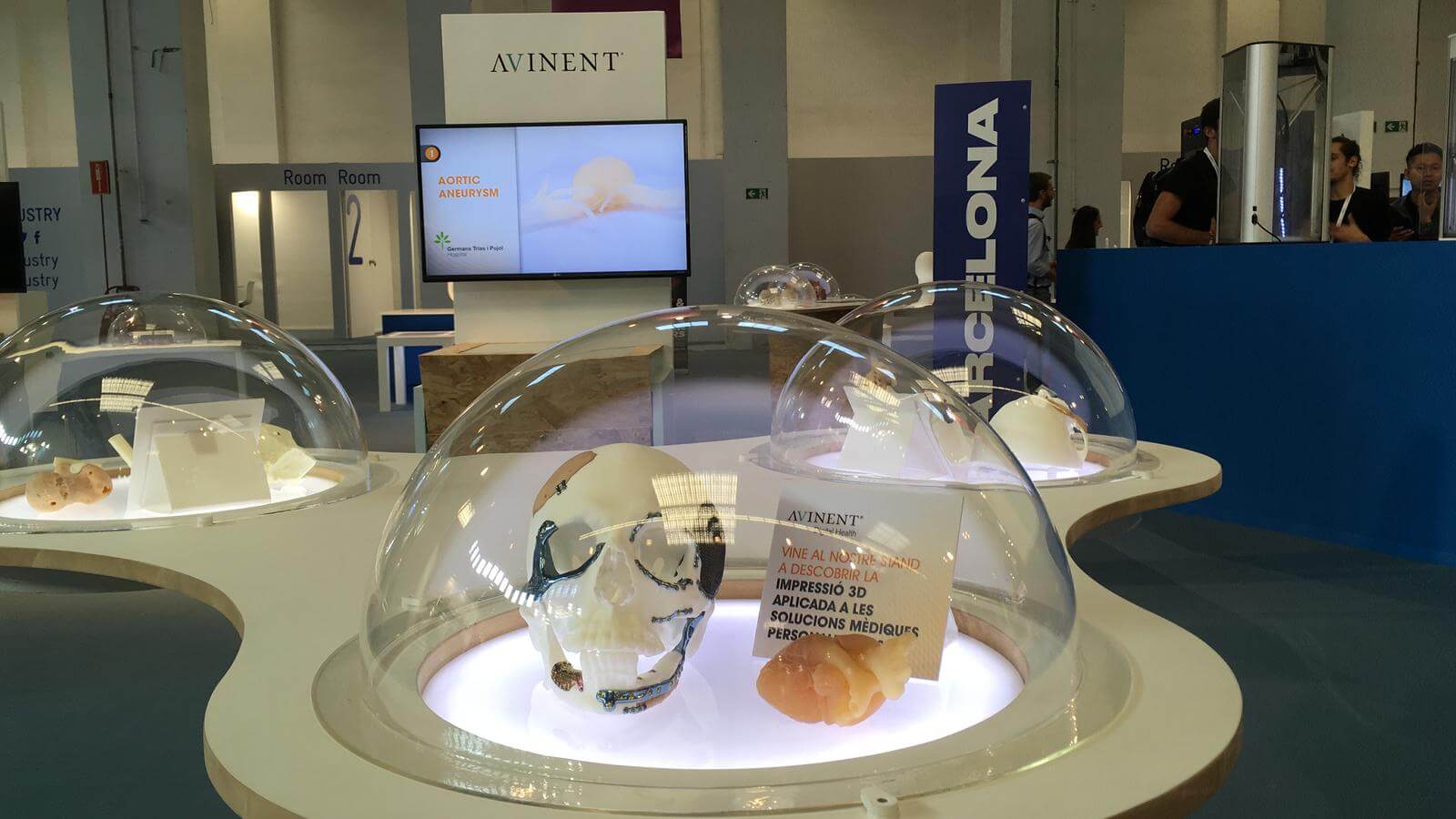

AVINENT was present at both congresses that were being held at same time, with a stand at each. At one, in the area dedicated to In3dustry, AVINENT provided a wide range of anatomical models printed in 3-D that had been used in the twelve real success stories presented in the “3D for Health. Success stories” cycle. At the other, in the Healthio area, the company displayed the printing capacity at its facilities, the technologies it uses, and exhibited one of the printers the hospitals or medical centres can acquire, the Form2 by Formlabs.