Before beginning oral rehabilitation work, it is very important to thoroughly analyze the case and discuss treatment expectations with patients. This way we can determine the best treatment for the patient. Once the decision has been made regarding

Oral rehabilitation step by step:

1. Preparatory steps: Before beginning oral rehabilitation work, it is very important to thoroughly analyze the case and discuss treatment expectations with patients. This way we can determine the best treatment for the patient. Once the decision has been made regarding

the type of prosthesis to use, implant treatment is planned. Ideally, the restoration will guide the implants rather than the implants guiding restoration. A preoperative tooth guide can be a great help.

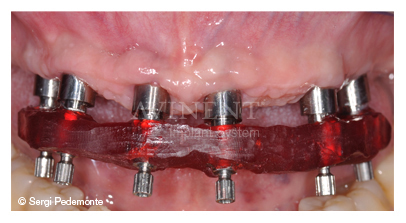

2. Definitive mold on implants: Use of an individual impression tray and splinted implants is recommended.

3. Wax rim test: The vertical dimension, occlusal plane, centric relation, midline, smile line, canine lines, and lower lip curve are determined.

4. Screw-in teeth mount: This allows us to check the parameters of the bar.

5. Passive proof: This allows us to check the work mold.

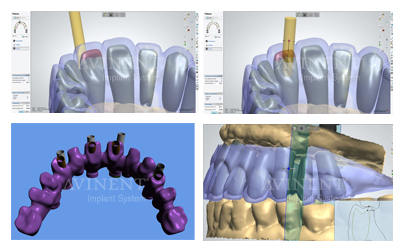

6. Design of structure in the laboratory using the 3Shape Communicate application. We can examine the structure design and choose the most appropriate one for each case with the laboratory.

7. Milling the structure: files are received at the milling center with the necessary information for milling the prosthetic structure.

8. Metal proof: We check the fit of the structure and take a bite impression

9. Ceramic proof: Several proofs are made until we achieve the desired aesthetic and functional result

10. Finishing

1. Flawless fit: at the base and screw.

2. Better ceramic adherence: especially on CoCr.

3. Stability after ceramming: the structure does not flex after multiple firings.

4. Versatility of technique: Structures can be obtained from molds, acrylic structures, or CAD files. Angles can be corrected.

5. Good quality-price ratio: savings on prosthetic attachments.

6. Universal: can be used with any implant system.

7. Homogeneity and hardness: allow free extensions and complex structures.

8. Variable materials: structures can be made of CoCr, Ti or Zi.

1. Fradeani M. Esthetic Rehabilitation in Fixed Prosthodontics. Vol 1: Esthetic Analysis: A Systematic Approach to Prosthetic Treatment. Chicago: Quintessence, 2004

2. Coachman C, Salama M, Garber C, Calamita M, Salama H, Cabral G. Prosthetic gingival reconstruction in a fixed partial restoration. Part 1: introduction to artificial gingival as an alternative therapy. Int J Periodontics Restorative Dent 2009;29(5):471-7

3. Serra-Prat J, Cano-Batalla J, Cabratosa-Termes J, Figueras-Àlvarez O. Adhesion of dental porcelain to cast, milled, and laser-sintered cobalt-chromium alloys: Shear bond strength and sensitivity to thermocycling. J Prosthet Dent. 2014

4. Fernández M, Delgado L, Molmeneu M, García D, Rodríguez D. Analysis of the misfit of dental implant-supported prostheses made with three manufacturing processes. J Prosthet Dent 2014; 111:116-123